Industries Solution

Semiconductor Manufacturer

Service:Rail transportation

Regions covered:From Shanghai to Hong Kong

Main products handled:Semiconductors

Issue:In addition to rail transportation, customs declarations needed to be handled.

Response:We spent two days preparing the cargo for shipment at the warehouse and making customs declarations. Then, on the third day we began transporting the cargo via rail containers, and spent a whole day delivering the cargo to the warehouse in Hong Kong.

Result:By having the SBS Group handle the transportation, costs were successfully reduced by around 20% compared with truck-based transportation.

Precision Equipment Manufacturer

Service:Export of precision equipment to China

Regions covered:From Japan to China

Main products handled:Polishing equipment

Issue:We received a request to perform a series of logistics operations to travel to a site of a domestic manufacturer manufacturing and selling polishing equipment, collecting the relevant cargo, packaging the cargo, completing customs procedures, transporting the cargo by sea, transporting the cargo over land in China, and delivering the cargo to the plant.

Response:We proposed packing methods to protect the contents from impacts during transportation and cargo handling and to prevent damage and other cargo accidents, and suggested packaging materials that are high strength and have a minimal environmental impact.

Result:The export packaging was designed so that the rating plate of the equipment was visible with the cargo in its packaged state. By making the rating plate, which lists information about the performance of the equipment and rated values for usage limitations, clearly visible, we were able to prevent mistaken equipment pickups during delivery operations.

Beverage Manufacturers

Service:Marine transportation of beverages

Regions covered:From Spain to Tokyo

Issue:When importing goods by marine container, the bonded transportation of containers, cargo handling and cargo storage in Japan can be costly and time-consuming when conducting food analysis of commercial products.

Response:Since performing food analysis on cargo once it has been imported by container carries the risk of being costly and time-consuming, we suggested to the importer that a small amount be imported by air and the analysis and the inspection be performed in advance in order to reduce costs and time, thus mitigating the risk of goods failing inspection.

Result:As food analysis had been completed in advance, we avoided excessive costs (transportation, handling, storage, etc.) and shortened the time required. The importer rated our performance highly, leading to a long-term project.

Medical Device Manufacturer

Service:Developing a Scheme Covering Procurement Logistics to Sales Logistics

Regions covered:From Japan to other countries

Main products handled:Medical devices

Issue:We needed to be flexible in handling logistics between Japan and overseas locations, such as shipping product components in small lots from bonded warehouses close to manufacturing facilities and supplying by VMI.

Response:The SBS Group transported the product components from Japan to bonded warehouses overseas. The components were taken to the overseas plant, and following manufacturing and packaging, were returned to a bonded warehouse for storage.

Result:Cost reductions were achieved by only delivering the needed components to overseas manufacturing sites based on purchase orders, and then transporting the products to each site following manufacturing and final assembly.

Apparel Manufacturer

Service:Air transportation

Regions covered:From China to Narita

Main products handled:On-line sales, discount sale items

Issue:In the lead up to the release date, the provision of secondary materials from Japan to the Chinese factory was finished on schedule, but despite preparations being complete on the Japanese side, as production of the outer fabric scheduled to be prepared domestically in China was several weeks behind, it was determined that production would not be completed in time.

Response:The decision was made to abandon the original plan to ship the goods by sea, and to book flights to ensure delivery times were met even if at a loss, but it was determined that inspections on the Chinese side would not be completed in time. For this reason, we suggested to the importer that inspections be carried out on the Japan side, and we held discussions about the details of the inspection work with the customer.

Result:Under the control of our customs clearance team, we were able to meet the desired delivery date by coordinating with affiliate companies, including bonded warehouses, inspection companies and transportation companies.

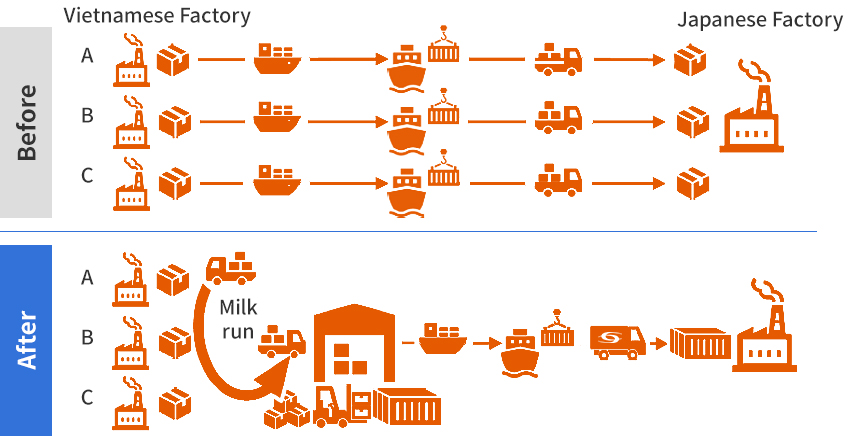

Milk-run logistics

Previously, orders would be shipped LCL one by one from each factory as soon as they were completed.

By consolidating all orders in a warehouse in Vietnam, an improvement of:

・Trucking fees in Vietnam・Freight forwarding costs・Customs clearance and delivery fees in Japan

as well as streamlined delivery times and manpower necessary for unloading.

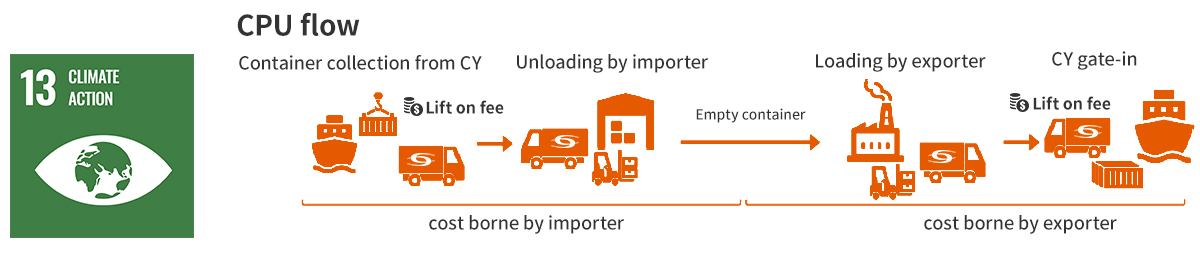

Container Round Use (CRU)

Logistics scheme where an inbound container is directly re-used for export without being sent back to a depot or empties yard.

What are the benefits of CRU?

Transportation costs can be reduced as both the importer and the exporter shoulder less trucking costs compared to a regular shipment.

Moreover CRU is a sustainable mode of transportation reducing greenhouse gases from reduced waiting times at port, reduced traffic and improved fuel use.

Drawbacks

・Both importer and exporter factories/warehouses need to be located close each other ・Unloading and loading should be implemented within the same day ・Shipments needs to be booked with the same shipping line and the same container size